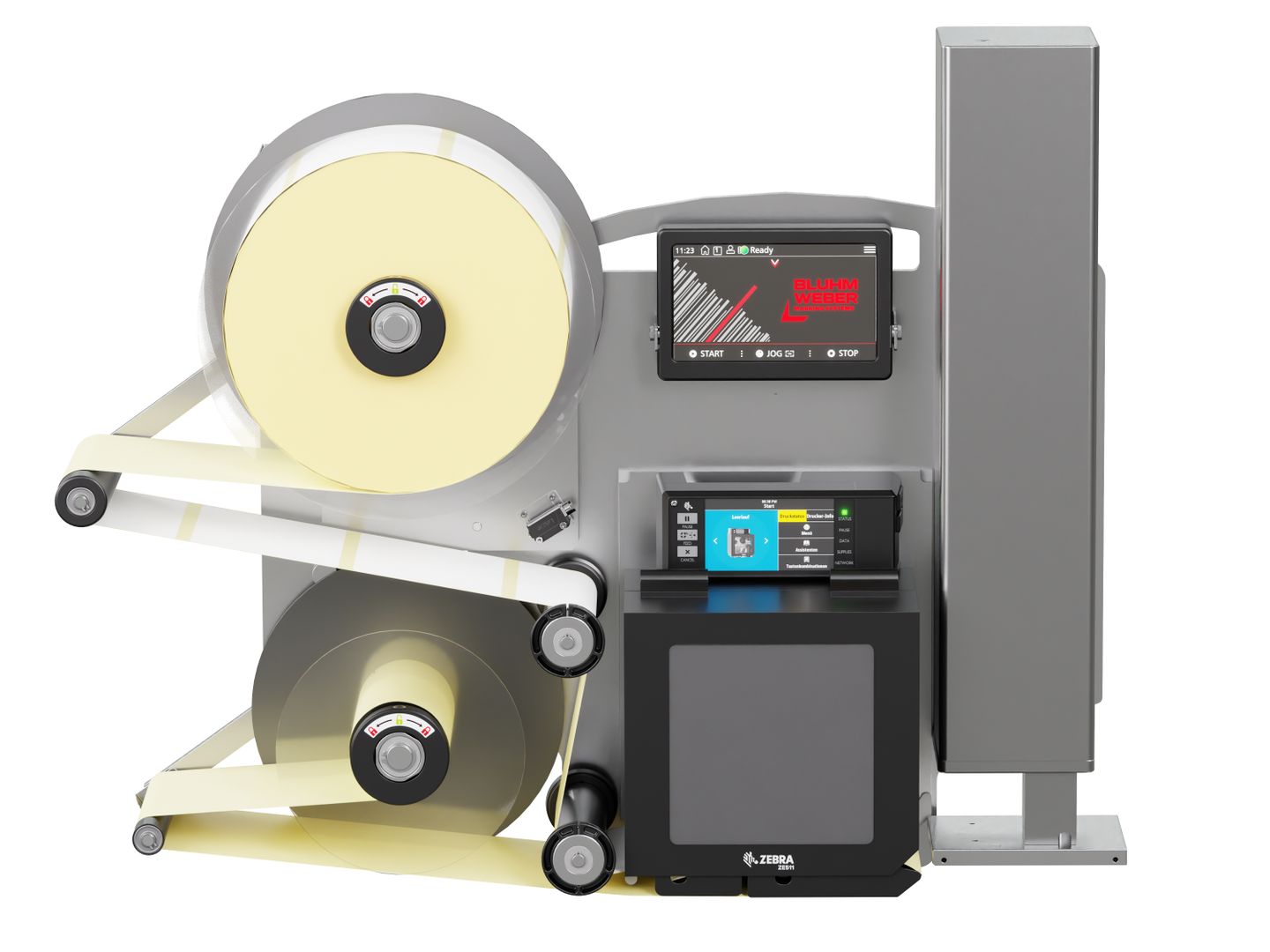

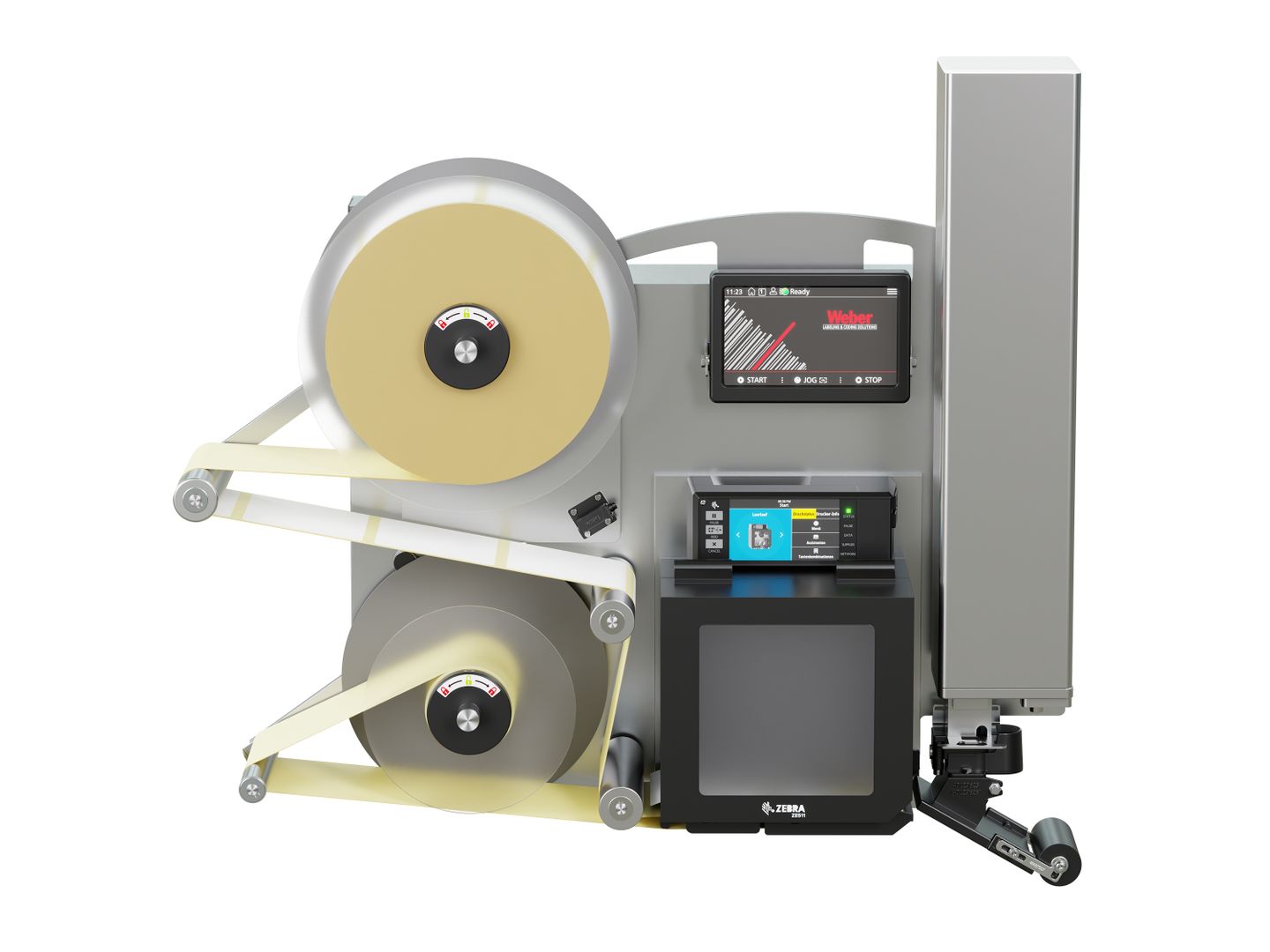

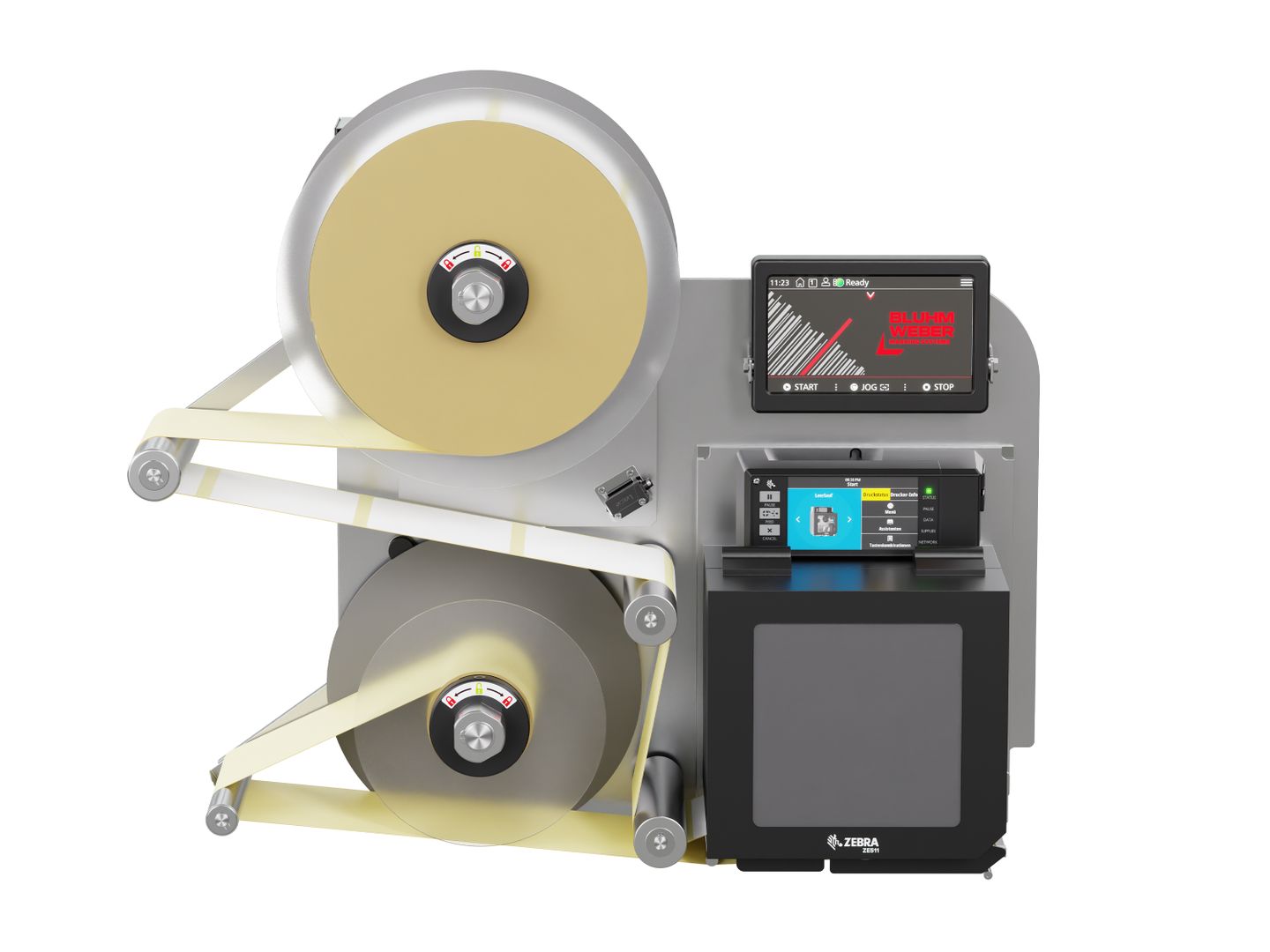

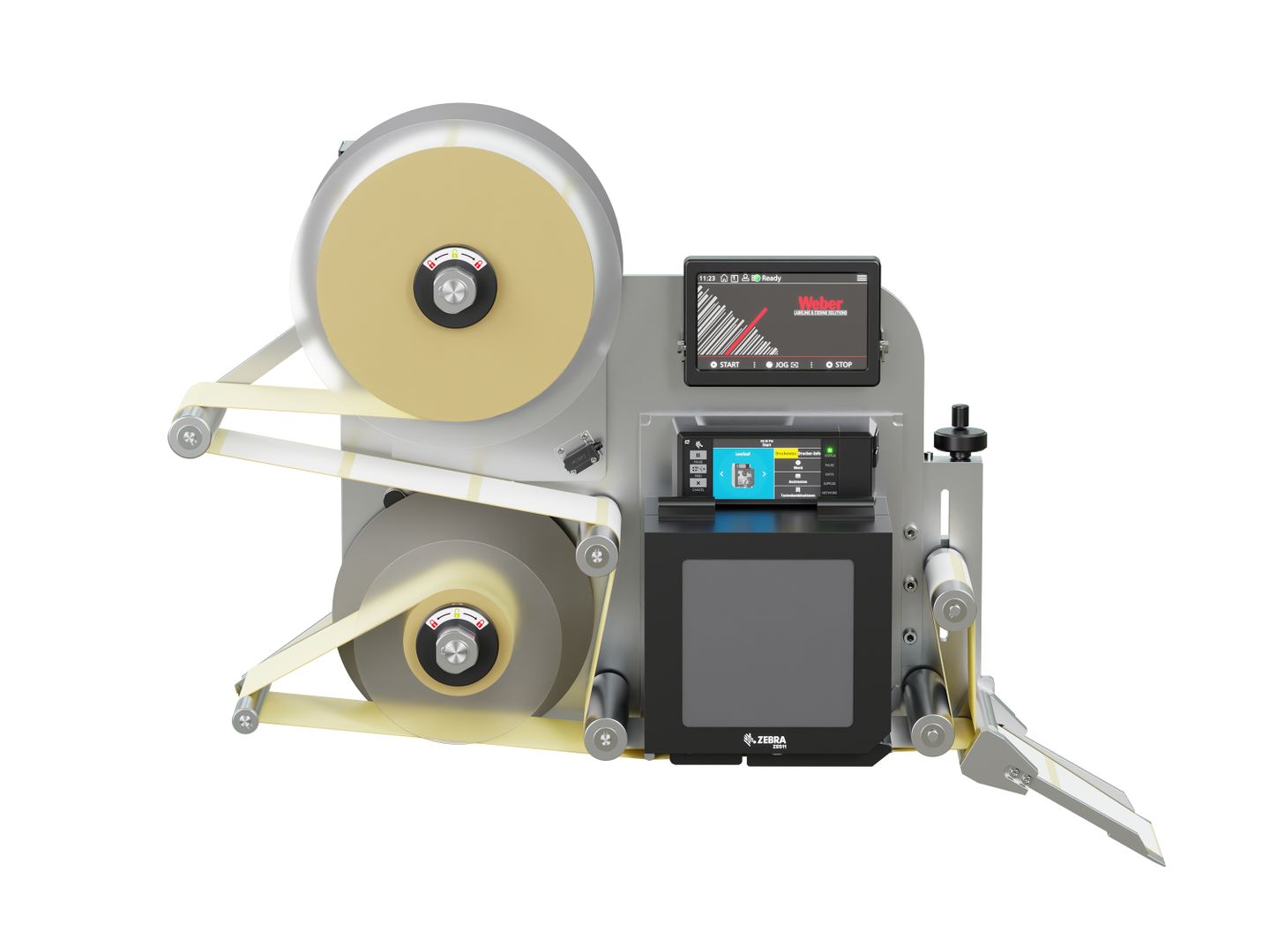

Two sides, one system: Efficient labeling

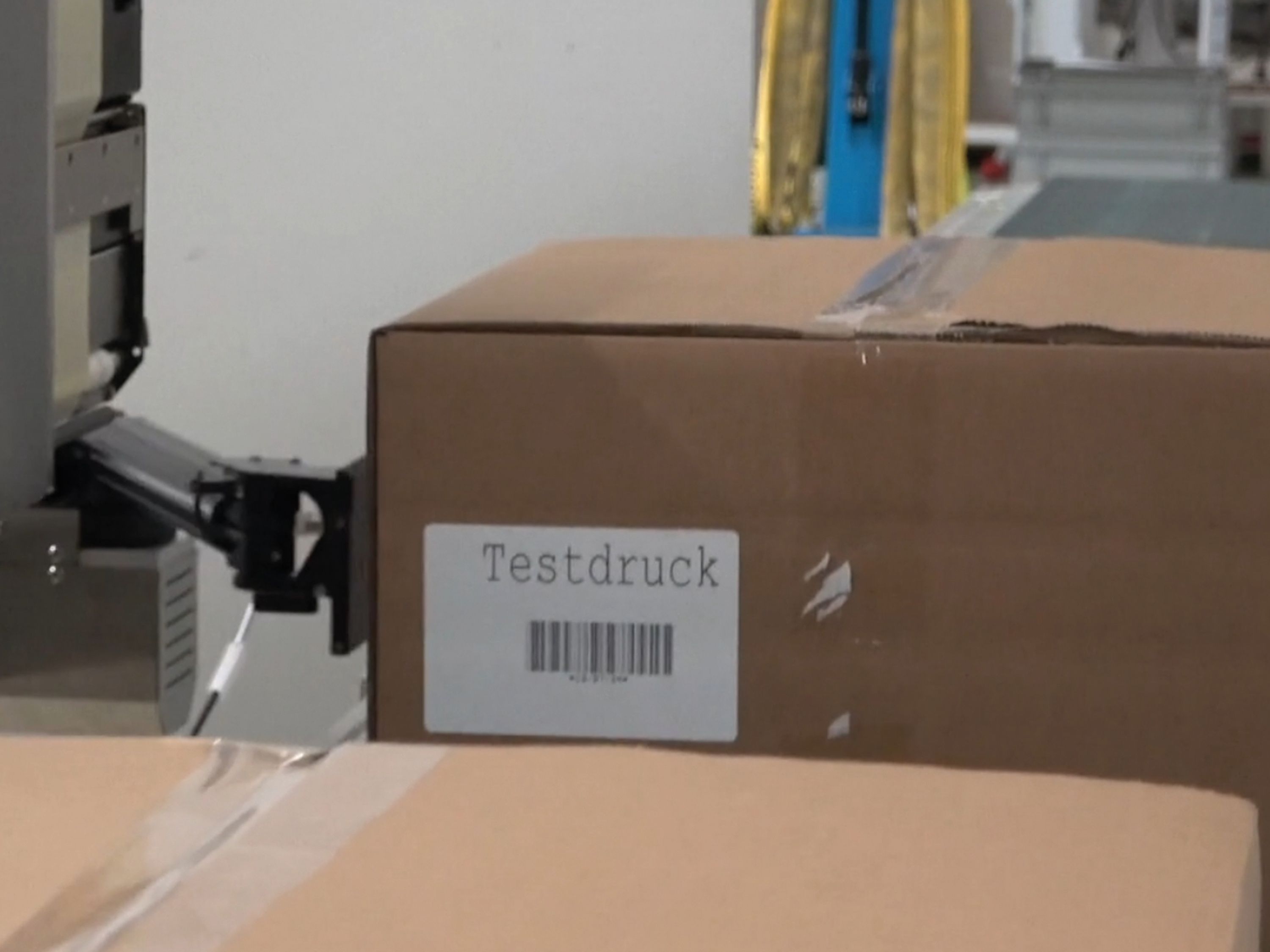

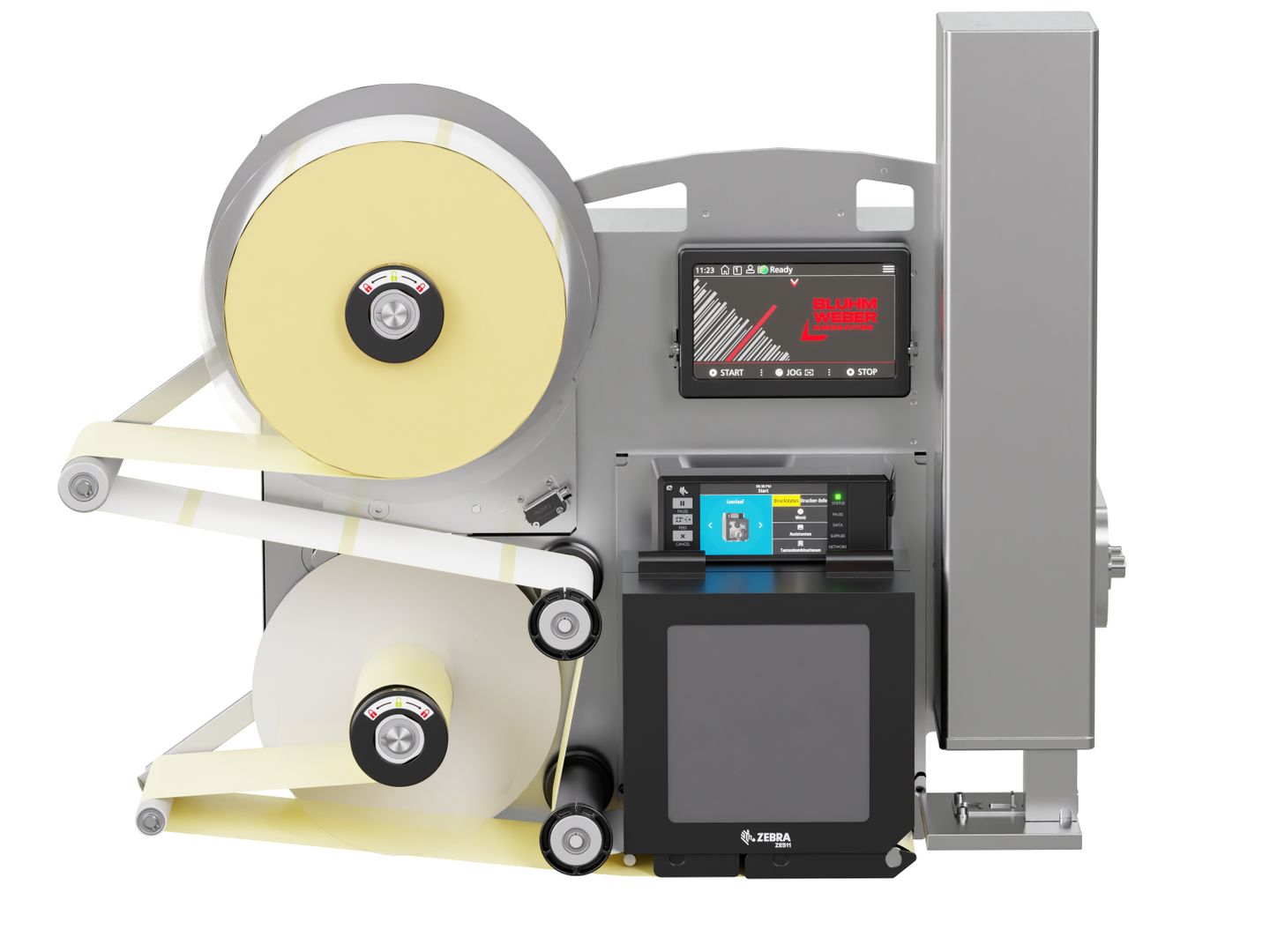

The Legi-Air 4050RR is a highly flexible labeling system for automated 1- or 2-sided labeling of carton packaging - ideal for industries such as pharmaceuticals, food and home care. Thanks to its compact design and the ingenious Rombid rotation system, the applicator enables precise label placement even with changing labeling modes - without mechanical modification. Thanks to the quick-change adapter, format changes are quick and tool-free. The tamp-blow process guarantees non-contact label application, with the tamp always parallel to the product surface. Print speeds of up to 400 mm/s and resolutions of up to 600 dpi ensure razor-sharp results - even with variable print data. Whether single or double-sided labeling: The Legi-Air 4050RR stands for process reliability, flexibility and quality in industrial labeling.