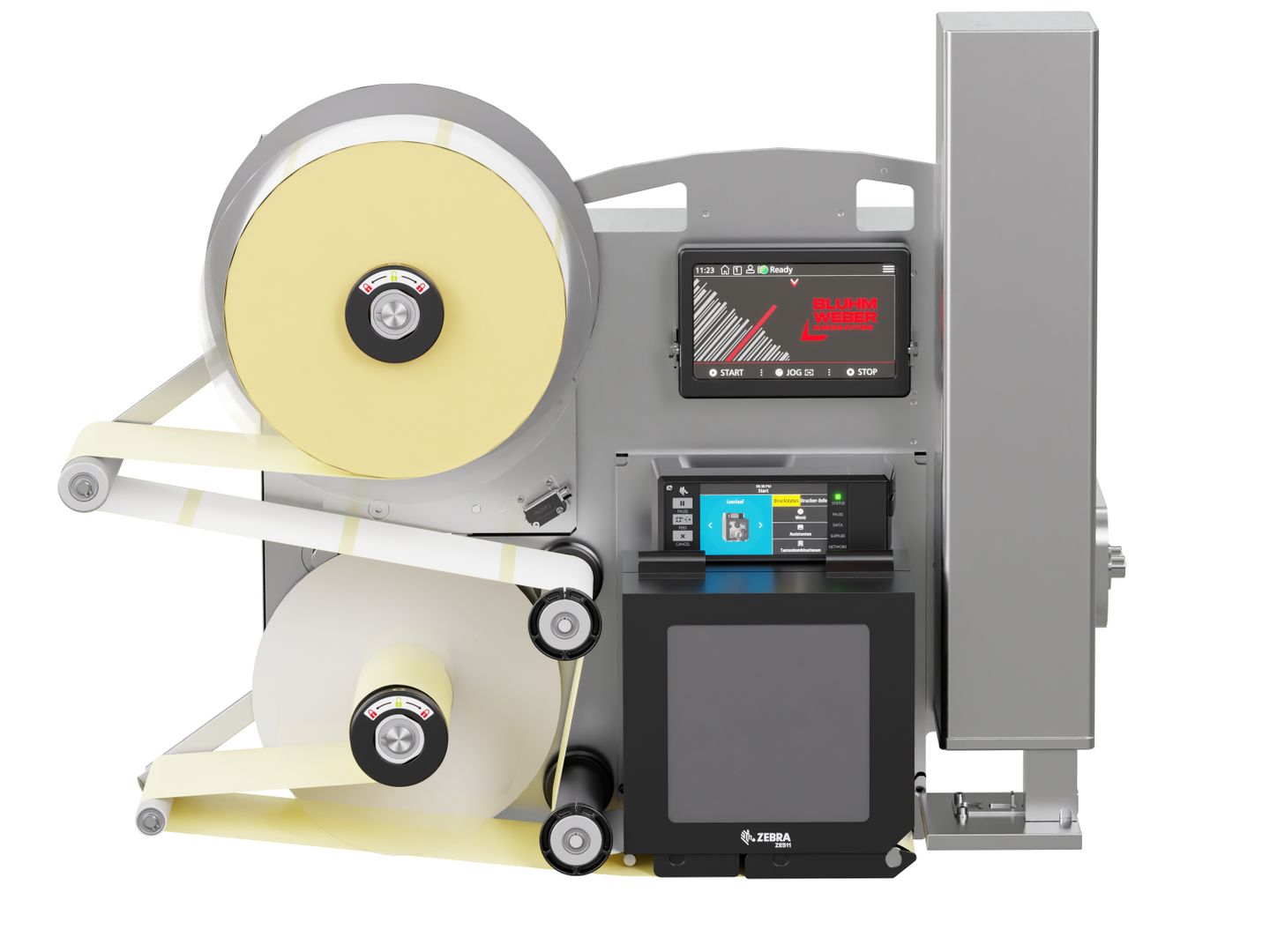

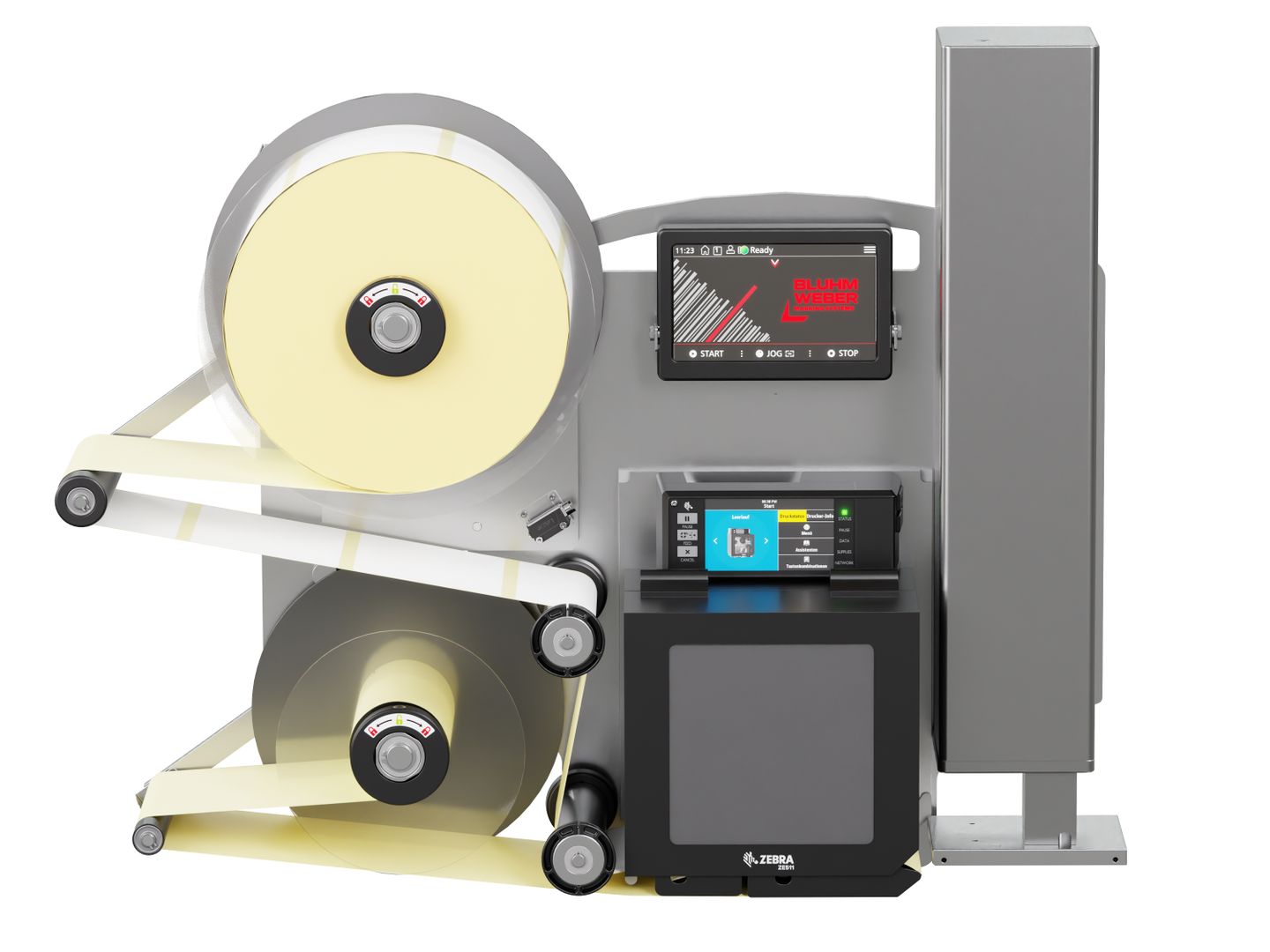

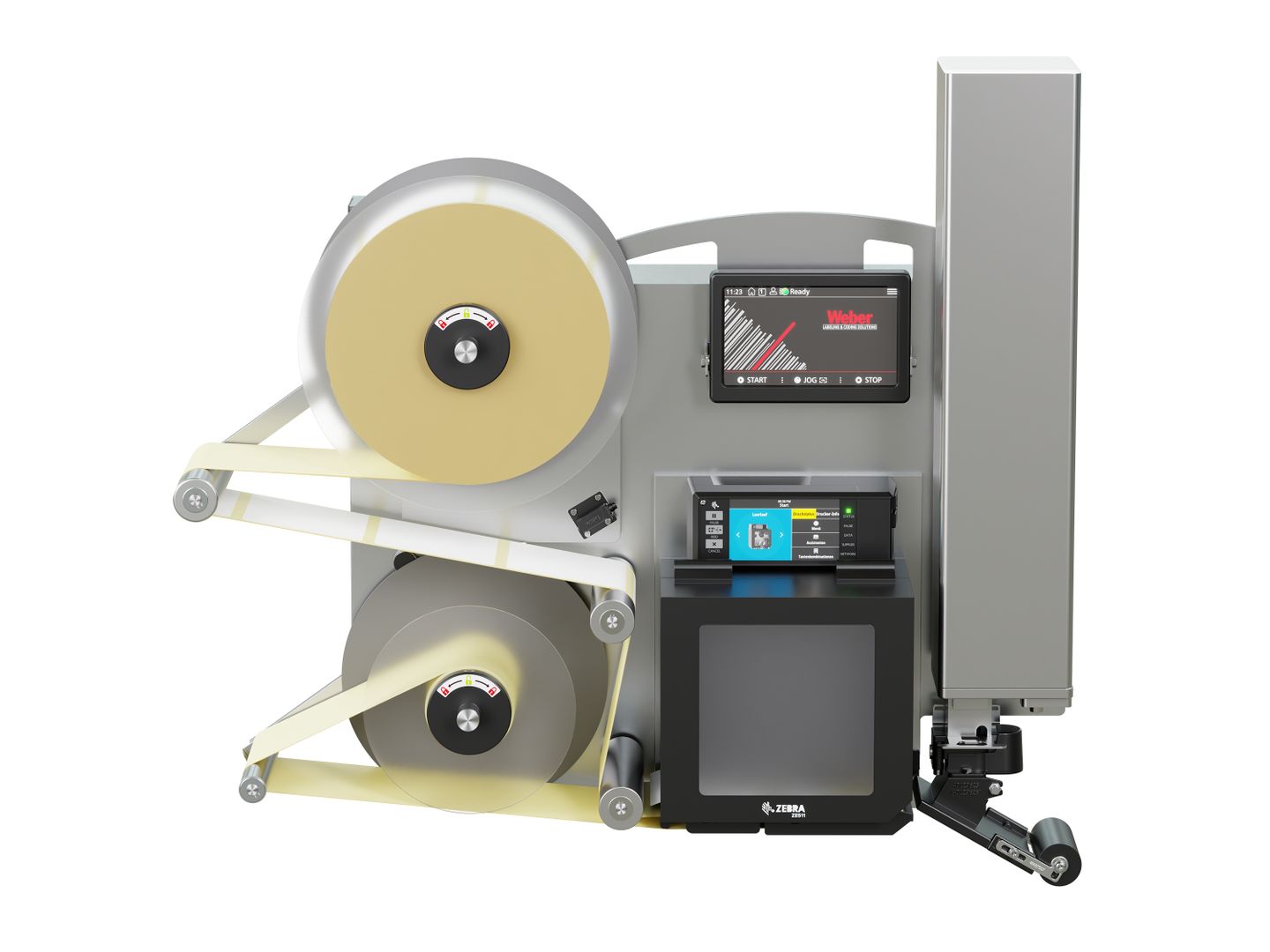

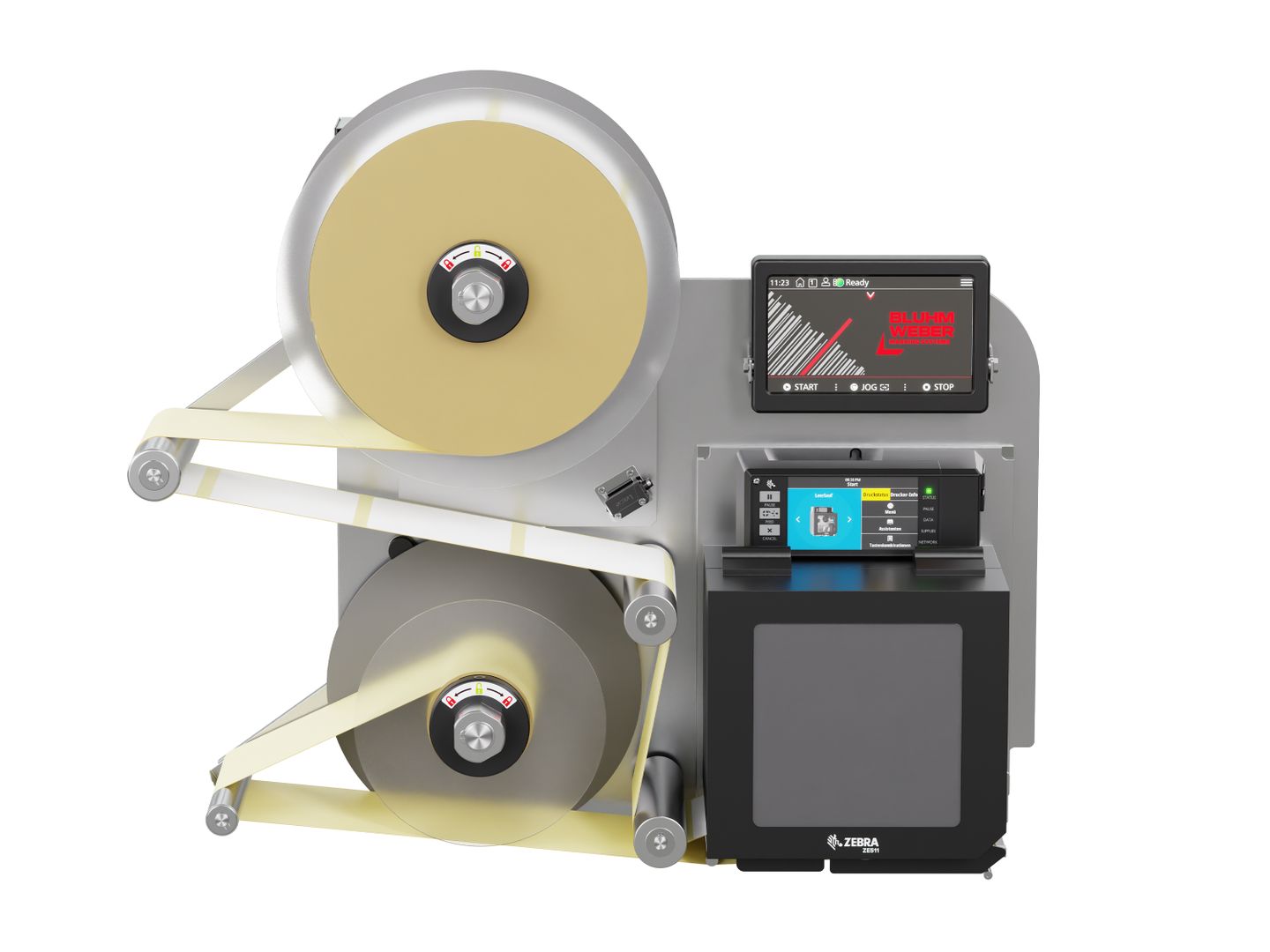

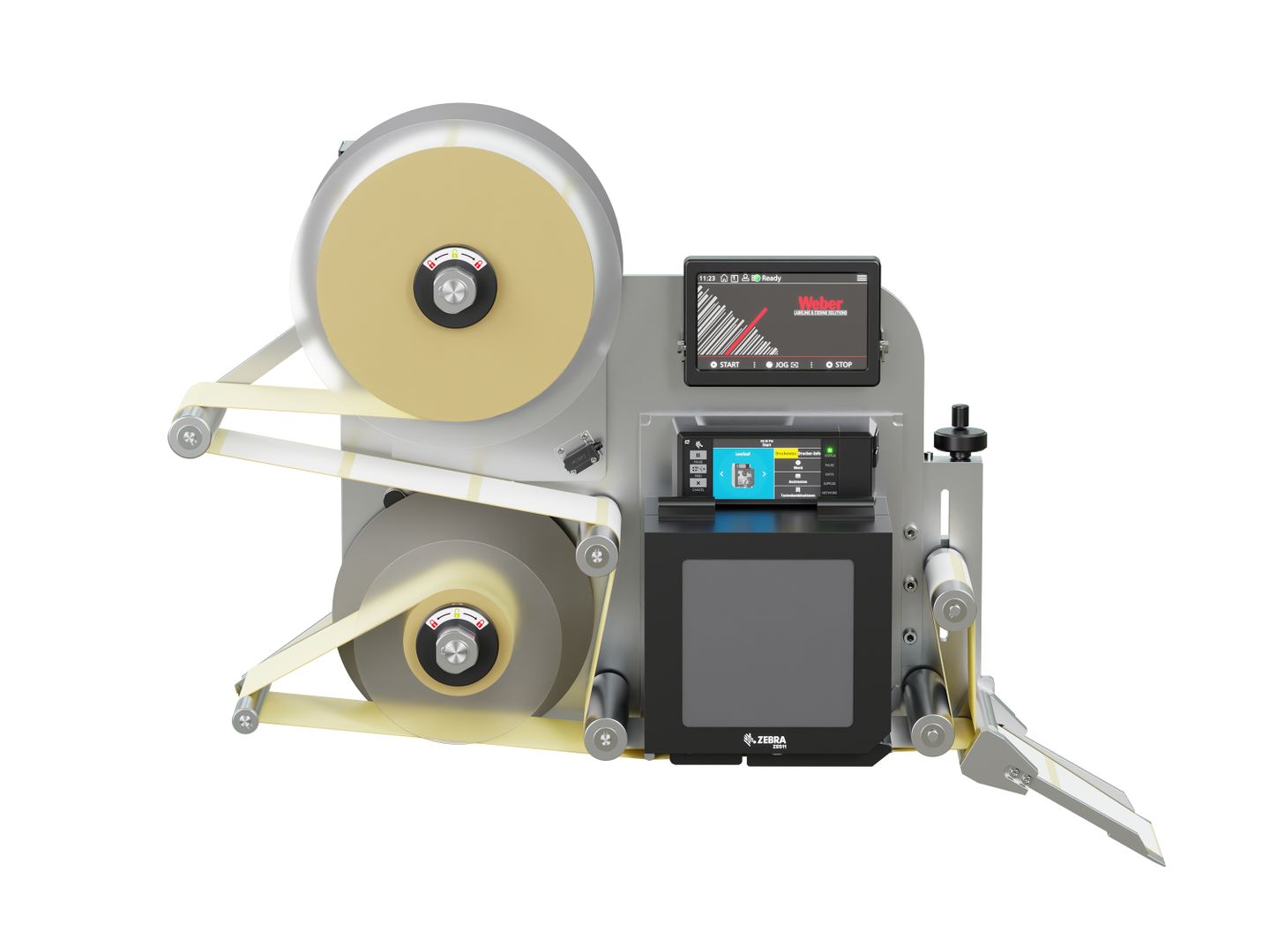

Electric labeler with high dispensing capacity

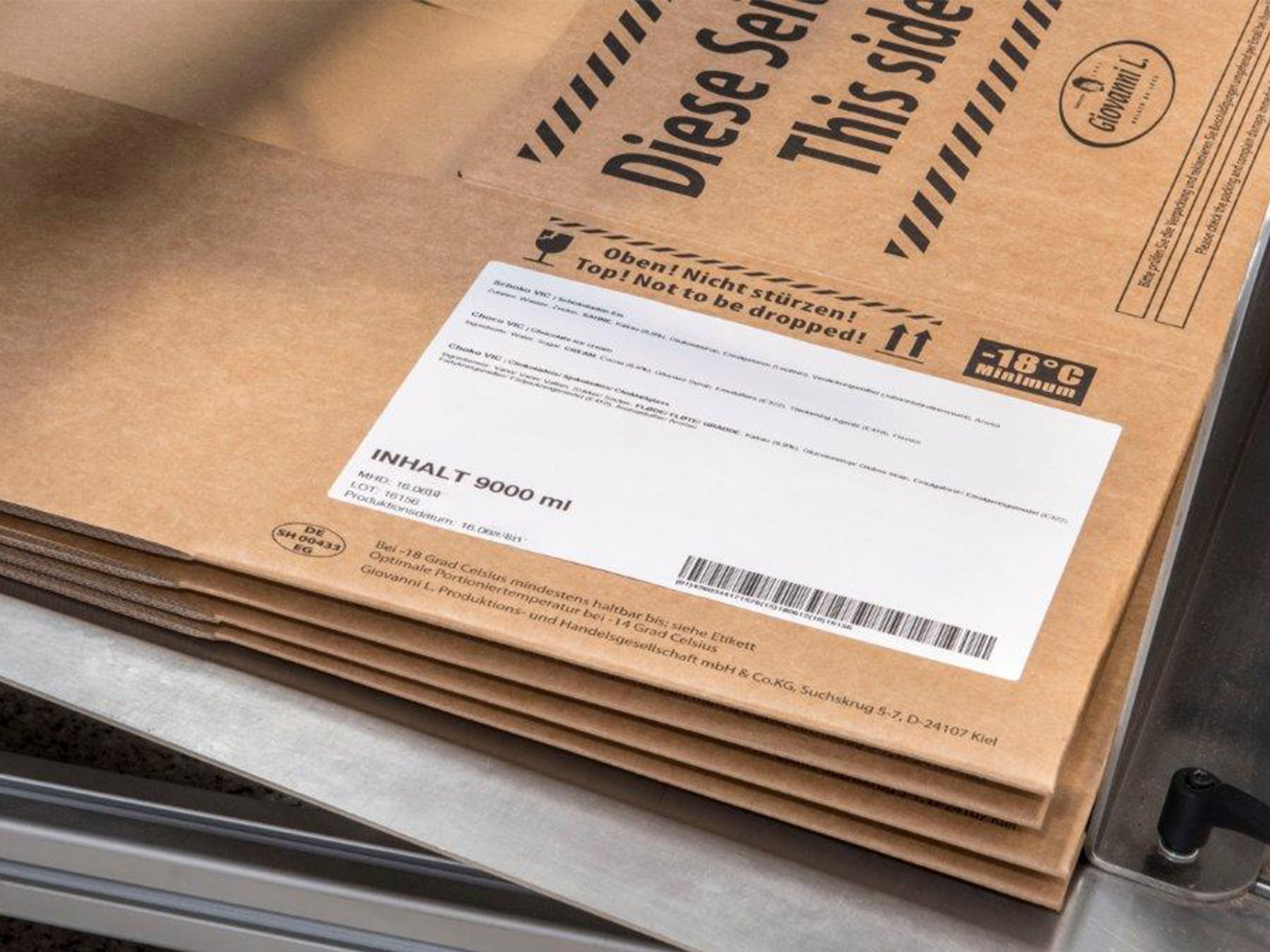

The Legi-E 4050B supports print modules from well-known manufacturers and offers a wide range of interfaces for flexible integration into your production environment. Its purely electric operation significantly reduces your energy costs by eliminating the need for compressed air. Labeling runs independently of the print module speed - even at conveyor speeds of over 300 mm/s - and processes different label sizes just as effortlessly as plastic labels, which are applied reliably and with reduced bubble formation.

All components come from our standardised mass production, which guarantees high availability and keeps costs low. The well-structured system design facilitates operation and enables maintenance without external technicians. With its compact design, the Legi-E 4050B can be easily integrated into a wide variety of production environments.