Weber Marking Systems’ easy-to-integrate label printer and dispensers are high-tech, advanced technological solutions designed and crafted to take part in industrial environments. Our product line ranges from identifying and marking the product itself – thus primary packaging identification – to marking or labeling the product’s packaging (e.g. boxes, case shippers in the case of pharmaceuticals, envelopes in the case of e-commerce) and last but not least, the identification and label-application on pallet.

Pallets are best known as tertiary packaging in the industrial jargon and consist of many boxes put together and wrapped in plastic film – thus palletized – for simplifying large badges transportation. However, pallets are not meant just to facilitate the transportation of goods, but aim also at guaranteeing safety and traceability. For this reason, production and the whole supply chain use pallets to track, trace and identify badges. In this article, we dive into pallet-identification and pallet-labeling, putting on the spotlight traceability and safety during shipping within different sectors, warehouses, and logistics.

Pallet identification through pallet labeling

Every day more and more industries are required to track their products, and this is the reason behind the wide variety of standards that coexist to regulate pallet identification. Multiple sectors such as the food, the pharmaceutical or the logistics industries need to ensure integrity, trustworthiness, and safety of their production through pallet labeling. This is why there is some common ground on pallet identification: the most widespread standards are, for example, the use of barcodes and the SSCC established by the GS1.

Structure of a pallet label

The logistics label is a standard label elaborated by the GS1 for identifying a pallet or package with a logistic or commercial goal.

The GS1 label is mainly divided in 3 sections and has a GS1-128 barcode which is the only information that must be included in any logistics label.

The top and middle sections of the label contain, respectively, spare information such as the name and address of the sender and receiver, and information about the package.

About the Serial Shipping Container Code (SSCC)

The SSCC (Serial Shipping Container Code) identifies univocally the logistics unit, thus the pallet, and allows each single unit to be tracked and traced along the supply chain: this means that it’s possible to track individually each physical movement of the logistic unit and the data flow associated to it. For instance, the SSCC is assigned by the producer of the product or by company that palletizes the unit.

Did you know…

The SSCC can be re-used 12 months after the dismantling of the logistic unit it had been attributed!

However, GS1 labels do not only involve the SSCC code, but also require including other codes such as the GTIN or badge number, the serial number and the best by date, all according to what is aimed to be identified and to the size of the package.

The pharmaceutical industry: pallet labeling for traceability and integrity

Labeling in the pharmaceutical industry is mandatory to guarantee the integrity and safety of the medicines and packages.

Indeed, the labeling process for this specific industry is called aggregation: a parent-child relationship established among packages; thus, the primary packaging must be identified with a code that is “connected” through a parent-child relationship with the secondary package whose label contains data that, at the same time, is associated to the data contained in the label applied on the pallet.

Do you want to know more about pharmaceutical identification?

Download the Whitepaper!How to label pallets

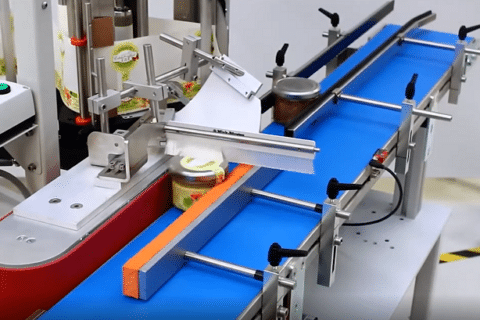

Weber Marking Systems has more than 50 years of experience in industrial labeling systems and is pioneer in the development and manufacturing of electric labeling systems. One of the protagonists within the electric label printers and dispensers portfolio is the pallet labeling machine AP182, an intrinsically safe and electrical system enclosed in a stainless-steel cabinet appropriate for harsh industrial environments.

The AP182 pallet label machine allows the application of two A5, GS1 logistic labels onto moving or stopped pallets. The system has an elevated performance, enabling the labeling of 90 pallets an hour or 120 pallets an hour applying a single label on a pallet. Thanks to a 180º degree tamp-pad, it’s possible to apply labels either in landscape or portrait position.

Weber Marking Systems not only meets the needs of tertiary packaging identification through the AP182: our LA 4050 E 2A, a pneumatic label printer and dispenser, allows the application of labels on two sides of a pallet thanks to a swing arm applicator.