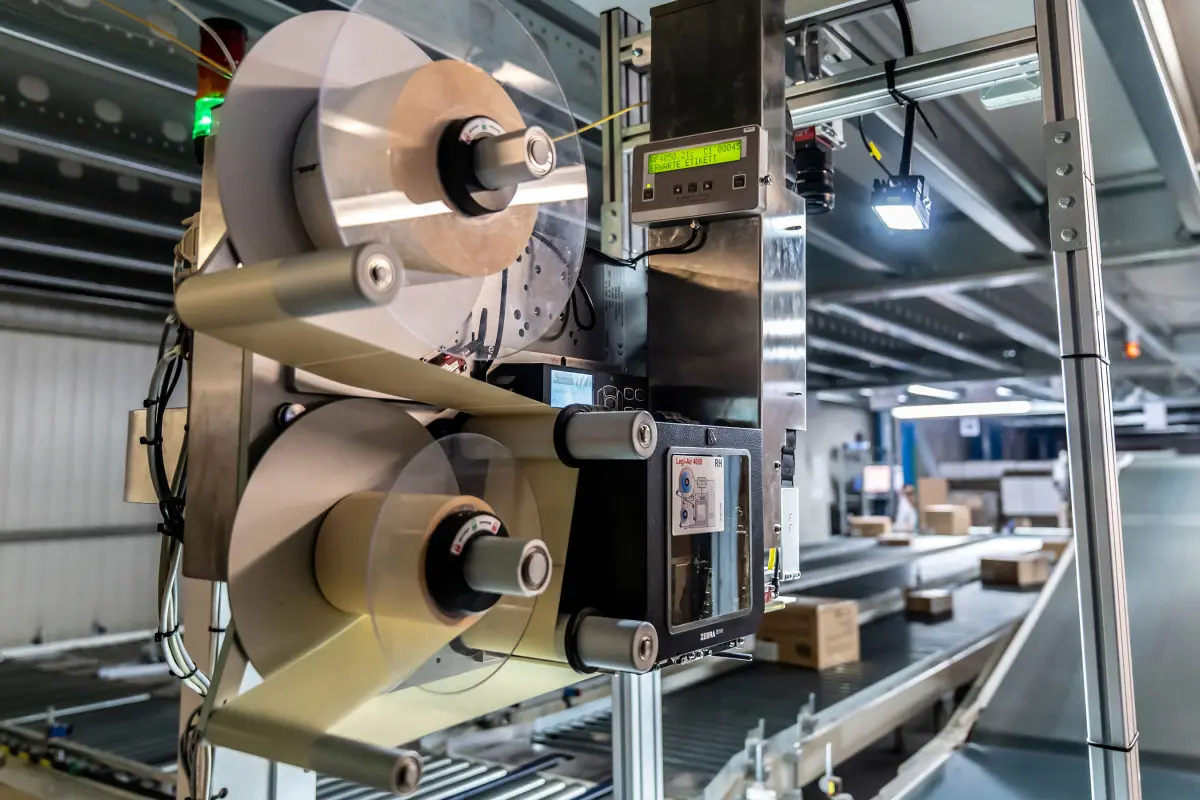

Variable labeling

Variable dispensing strokes and integrated sensors enable labeling of shipping units of different heights on one and the same line.

You have currently selected the following location:

Now switch to the following location:

Our automatic labeling and coding technologies speed up your processes and reduce your costs. From order picking to shipping, goods movement and warehousing, all processes need to run smoothly. Easy-to-read labeling is essential and a priority to ensure that goods, components and merchandise are stored safely, arrive quickly and can be traced if necessary. Modern just-in-time production saves storage space and meets individual customer needs. However, it also demands a high degree of flexibility and responsiveness in labeling and coding. We help you select the right system and ensure that it improves your processes. We include all our technologies in the decision-making process and, if necessary, combine them to create a solution tailored to your needs.

Coop is known far beyond the borders of Switzerland. The retailer has the densest network of sales outlets in Switzerland. The distribution centre in Schafisheim is home to Switzerland's largest bakery. From here, the branches are supplied with fresh bread every day. Marking systems from Bluhm Weber Group guarantee the…

Beck Packautomaten GmbH & Co. KG, based in Frickenhausen near Stuttgart, specialises in the fully automatic packaging of a wide variety of products in film and paper. To make its packaging systems even more user-friendly and sustainable, Beck Packautomaten has now developed a new machine concept. An important component is…

Kraus Maschinenbau GmbH from Spaichingen developed the FK Codingline for its customers to efficiently label and print folding cartons. With this modular system, labels can be applied to products all around without compressed air. Thanks to the integration of Bluhm Weber Group technology, high print quality and production speed are…

Eisbär Eis GmbH was founded in Plummendorf in 1992. Its customer base quickly expanded from regional buyers to national and later European food retailers. Today, over 18 million litres of ice cream are produced here every year. Despite its expansion, Eisbär is still family-owned. Just like its supplier of marking…

ALPLA stands for ‘Alpenplastik’ (Alpine Plastics). The company was founded in Austria in 1955 and became known throughout the industry for its specially developed ‘Alplamat’ injection moulding machine. Today, the group has 180 sites worldwide. In Berlin alone, 180 employees work around the clock to produce more than 1.3 million…

It is really frosty at minus 24 degrees Celsius in the logistics centre of frozen food and catering system provider Apetito at its main site in Rheine. The frozen food manufacturer relies on label dispensers from Bluhm Weber Group, which apply labels to packages reliably despite the cold.

Weber Marking Systems is a leading full-service provider of industrial marking technologies. With a focus on innovation, quality and sustainability, we develop cutting-edge labeling and coding systems that meet the requirements of our customers in every industry sector. Our international sales network guarantees excellent world-wide support and service. No matter what challenges your application presents: We have the necessary experience to work with you to find the optimum solution.