Industrial marking and coding is important for many different reasons (laws, automation, logistics etc.) and part of the workflow at multiple stages of the production line. Due to different surfaces, environments and applications, each sort of packaging might place different demands on the marking system. There are good reasons for companies to use various technologies in one single factory. Learn how to get the most out of your labeling systems and inkjet printers!

Marking primary packaging

The primary packaging encloses the actual product and comes into direct contact with it. Beverage bottles, cosmetic jars and chip bags, for example, belong in this category. The packaging material protects the internal product with its barrier properties and also has a major impact on its consistent quality.

Markings on primary packaging are also important for consumer protection and information (e.g. best-before-dates). In many cases, certain marking elements for product identification and traceability are required by law. That is why you will also usually find barcodes, data matrix codes or serial-, lot- and batch numbers on them. However, these codes are not only essential throughout the entire supply chain or in the event of a product recall. They also become more and more important for factory automation.

Primary packaging in the food and pharmaceutical industry in particular, must be food-safe. Cartons may allow critical substances from the prints on it to migrate on and into to the inner product. Inkjet printers with GMP-certified inks such as from Weber Marking Systems’ Markoprint series have been proven to eliminate the risk.

One more factor to consider is the environmental conditions within the production line. For example, if a plant area has to be wet-cleaned on a regular basis for hygiene reasons, the marking system positioned there might need a sealed enclosure with IP65 protection. This also prevents the ingress of dust and moisture, which can come with certain products and processing steps. Other obstacles are extremely hot and cold temperatures (e.g. in the freezer area) which are not beneficial for every electronic device in continuous operation.

Marking secondary packaging

The secondary packaging is also known as sales packaging and is supposed to catch the consumer’s attention in retail. It encloses the primary packaging and has no direct contact with the contents. Instead, it might have additional barrier functions, serve for decoration, informational and promotional purposes (e.g. win codes) as well as improve product transportation. On top of that, it can aid brand protection and consumer safety by holding tamper-evident features. For prescription drugs packaging sold in the European Union, it is even required by law according to the Falsified Medicines Directive 2011/62/EU.

Since manufacturers must ensure the traceability of their products, secondary-packaged goods will often be marked with identifiers such as GTIN. They ensure the unique identification of trade items along the entire supply chain.

Examples of secondary packaging are, for instance, folding boxes for pharmaceutical products and variety packs with individually wrapped candies inside.

Typical marking solutions for primary and secondary packaging

| High-quality printed color labels with application-specific properties (removable, booklet, oil-resistant etc.) |

| Professional color label printers for printing multi-colored adhesive labels |

| Automatic label dispensers for precise and fast application of pre-printed labels |

| Print-and-apply labeling systems for simultaneous application and printing of labels with variable data |

| Seal labeling machine to apply seal stickers as a temper-evident feature to packages |

| Industrial inkjet printers for fast, contactless and cost-effective direct marking on absorbent and non-absorbent substrates. |

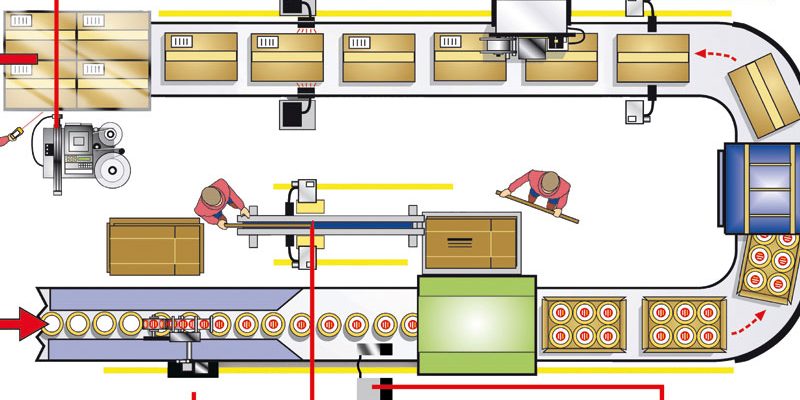

Marking tertiary packaging

Tertiary packaging is used to prevent transport damage and simplify logistics. It typically involves transport packaging such as cardboard boxes for shipping or shrink-wrapped carton trays. The focus is on uniform and reliably readable markings.

Typical marking solutions for tertiary packaging:

| Barcode labels for logistics-specific identifiers such as the Serial Shipping Container Code (SSCC) |

| Professional label printers for printing individual labels for logistics, manufacturing and trade | |

| Piezoelectric inkjet printers for marking cartons for internal logistics, where they can partially replace labels (see our comparison here) |

| Efficient pallet labelers which print and apply labels to pallets on two or more sides |

| RFID labelers and suitable RFID labels that allow automatic identification of multiple products or containers at once and without line of sight |

Weber Marking Systems is your partner

You want to learn more about how to label your various packages efficiently and reliably? Talk to the marking and coding experts at Weber Marking Systems! We are happy to arrange a free on-site consultation for your company:

Get a FREE expert consultation